Liquid packing equipment plays a significant purpose while in the productive and precise packaging of a amount of liquid items. Employed throughout industries which includes foods and beverage, prescribed drugs, cosmetics, and chemicals, this machinery means that merchandise is crammed, sealed, and packed swiftly, hygienically, coupled with minimal squander. As requirement for precision and velocity will increase, modern liquid packing products has grown to become more recent, presenting Improved automation, adaptability, and dependability.

At its core, liquid packing equipment encompasses quite a few built-in methods that function properly collectively to fill, seal, and put together liquid solutions for distribution. These devices could consist of liquid fillers, capping machines, labelers, and carton sealers. The principle aim is always to transfer liquid from your storage tank or reservoir into containers including bottles, pouches, drums, or Bag-in-Box (BIB) formats with precision and effectiveness.

Distinct varieties of filling mechanisms are employed with respect into the viscosity of your liquid along with the type of container. Gravity fillers and overflow fillers are ideal for slim, no cost-flowing liquids like drinking water or juice, while piston and pump fillers are improved fitted to thicker, extra viscous substances for instance sauces, oils, creams, and gels. Some equipment uses flowmeters or weigh scales for making particular specific dosing, which is crucial in industries wherever solution regularity is essential.

Modern liquid packing gear typically includes person-helpful digital controls and touchscreens that let operators to change settings conveniently and watch effectiveness in actual time. Clean-In-Location (CIP) systems and chrome steel building manage hygiene expectations, Specifically important in meals and pharmaceutical purposes.

One particular standout solution in just this industry is provided by brand names like Flex Pack Services & Materials in Australia. They structure and manufacture versatile, semi-automated and handbook liquid packing machinery personalized to precise generation demands. Their equipment can fill volumes from 0.5 to one,000 liters and cope with several packaging formats, from bottles and casks to massive industrial containers.

The main advantages of utilizing liquid packing devices are wide ranging: increased production speed, decreased labor fees, minimized merchandise wastage, and improved packaging regularity. For companies aiming to boost operational efficiency and product top quality, committing to significant-good quality liquid packing gadgets are an intelligent and essential go.

In conclusion, liquid website packing products and solutions are a cornerstone of recent manufacturing, providing the precision and satisfaction needed to fulfill currently’s aggressive current market requires.

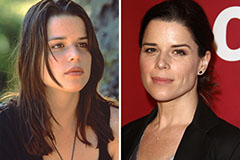

Neve Campbell Then & Now!

Neve Campbell Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now!